Comminution and classification technologies of iron ore

Introduction Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production. Most of the high-grade hematite iron ores are In a typical iron ore mine, the primary crushing process involves the use of a large gyratory crusher, which can crush large rocks and ores into smaller pieces. primary crushing process for iron ore mines

get price

Developments in iron ore comminution and classification

AG and SAG mills are coarse grinding devices; they consist of a tumbling drum with 25–40% volume filling of ore. They are fed with run-of-mine ore or primary Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A The six main steps of iron ore processing Multotec

get price

Primary Crusher an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. AMIT 135: Lesson 5 Crushing Mining Mill Operator

get price

Gyratory and Cone Crusher ScienceDirect

Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to This paper presents an economic analysis of a mine-to-crusher model to estimate and minimize the operating expenses of an open-pit iron mine located in northern Brazil. The activities at this A Mine-to-Crusher Model to Minimize Costs at a

get price

Simulation and optimization of gyratory crusher performance

Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, McLanahan What Type of Crusher Is Best for

get price

Iron ore BHP

How is iron ore mined? From pit to port, our iron ore undergoes a series of processes before export. First, we explore the geology of the region to find the best iron ore prospects for our operations. Once the ideal site has been chosen, the ore is drilled and blasted. It is then transported to the primary crusher for processing.The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). Developments in iron ore comminution and classification technologies. A. Jankovic, Primary Crusher an overview ScienceDirect Topics

get price

Simulation and optimization of gyratory crusher performance

To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this paper. First, the discrete element method (DEM) analysis model of the iron ore based on the bonded-particle model (BPM) is established. On this basis, the impacts of the mantle Mine haul-truck capacity is an important factor at primary crusher installations, because it is cost-effective to integrate truck cycle time at the crusher station with mine/shovel operations. If a primary crusher dump pocket is undersized and unable to handle the mine’s trucks, then operators must slowly meter the ore into the receiving hopper.Crushing Plant Design and Layout Considerations 911 Metallurgist

get price

Iron Ore Rio Tinto

Rio Tinto Iron Ore. Our iron ore operations in the Pilbara comprise a world-class, integrated network of 17 iron ore mines, four independent port terminals, a 2,000-kilometre rail network and related infrastructure. Insights from data help us to explore and extract our iron ore efficiently. Today, we produce five iron ore products in Western A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.Crusher

get price

primary crushing process for iron ore mines

In a typical iron ore mine, the primary crushing process involves the use of a large gyratory crusher, which can crush large rocks and ores into smaller pieces. The crushed material is then transported to the surface using conveyor belts, where it is further processed and refined.Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of low energy consumption, low operating costs, and improving the energyProcessing of Magnetite Iron Ores–Comparing Grinding Options

get price

what are the equipment in iron ore crusher? LinkedIn

The most commonly used iron ore crushers are jaw crusher, cone crusher, and fine jaw crusher. what are the maintenance of primary ball mill? Feb 13, 2023The company finished off 2019 by winning a contract to supply a new primary jaw gyratory crusher for the Roy Hill iron ore mine in the Pilbara, Western Australia.thyssenkrupp extends gyratory crusher winning streak

get price

What is the process of crushing copper ore? LinkedIn

This is usually done using a primary crusher, which reduces the ore to pieces that are about the size of a soccer ball. Grinding: The crushed ore is then sent to a ball mill, where it is groundRio Tinto Iron Ore. Our iron ore operations in the Pilbara comprise a world-class, integrated network of 17 iron ore mines, four independent port terminals, a 2,000-kilometre rail network and related infrastructure. Insights from data help us to explore and extract our iron ore efficiently. Today, we produce five iron ore products in Western Australia including the Iron Ore Rio Tinto

get price

Iron Ore 2021 AusIMM

These issues are particularly relevant in high-capacity operations such as iron ore mining, where large machines are in continuous operation. This article describes the architecture, construction and advanced testing of a novel remotely operated robotic mechanism for assessment and removal of metal tramp from primary crusher chambers.iron ore mine in Brazil. The model correlated the mine phase operating costs with the P80 size resulting from blasting material. An economic database and key performance indicators (KPIs) were collected for the unit operations of drilling, blasting, loading and primary crushing in 2019, and they were statistically processed to estimate A Mine-to-Crusher Model to Minimize Costs at a Truckless Open-Pit Iron

get price

Six ways to take primary crushing underground Australian Mining

Scalping is usually recommended before a jaw crusher, whereas gyratory crushers can handle the excavated ore as such. This is because primary gyratories are not as sensitive to fines: they areIron ore crusher machine is a powerful machine that divides the iron ore, which exists unprocessed in nature, into small pieces to process after extraction. Iron ore crusher machine is utilised as a primary crusher, secondary crusher or tertiary crusher in crushing plants and has an important role in crushing the hardest stones and mines such as iron Iron Ore Crusher Machine Fabo

get price

Developments in iron ore comminution and classification

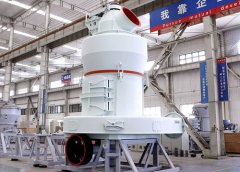

Hematite and magnetite, the two predominant iron ores, require different processing routes. High-grade hematite direct shipping ores Gyratory crusher: Primary: 1500: 200–300: 1200-over 5000: Jaw crusher: Primary: 1400: 200–300: Up to 1600: Horizontal impact crusher: Primary/secondary: 1300:Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeter-level fine materials. Primary crushing Jaw crushers are generally used for head crushing in iron ore production operations,Iron ore crushing equipment and process flow TY Ultrafine

get price

Brockman 2 mine

The Brockman 2 mine is an iron ore mine located in the Pilbara region of Western Australia, 60 kilometres north-west of Tom Price. It should not be confused with Rio Tinto's Brockman 4 mine, also in the area.. The mine is fully owned and operated by Rio Tinto Iron Ore and is one of twelve iron ore mines the company operates in the Pilbara. In 2009,

get price